Excellent Product Quality Through Rigorous Testing

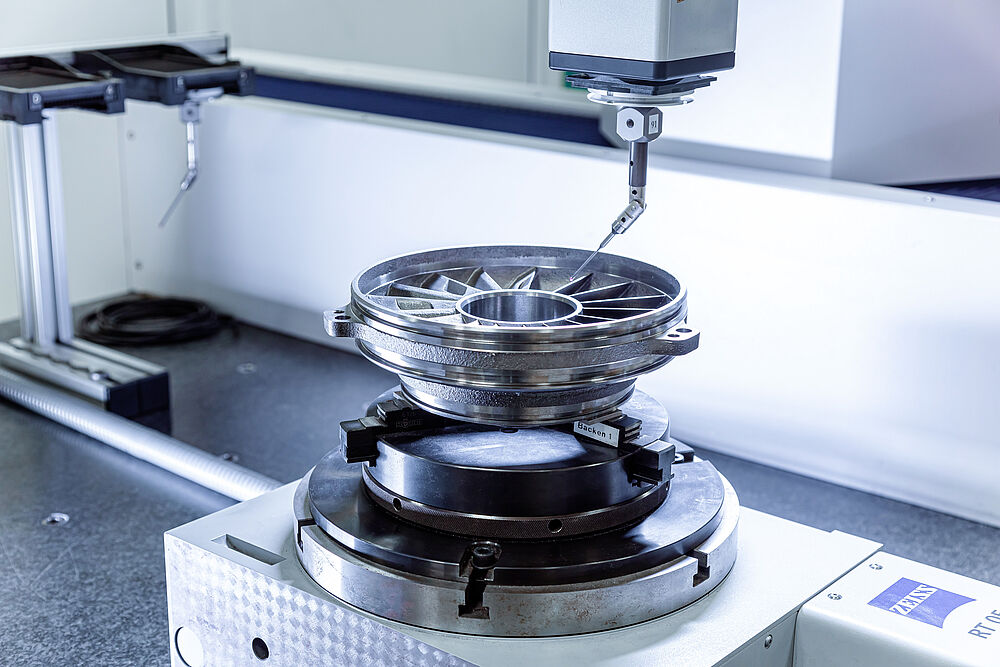

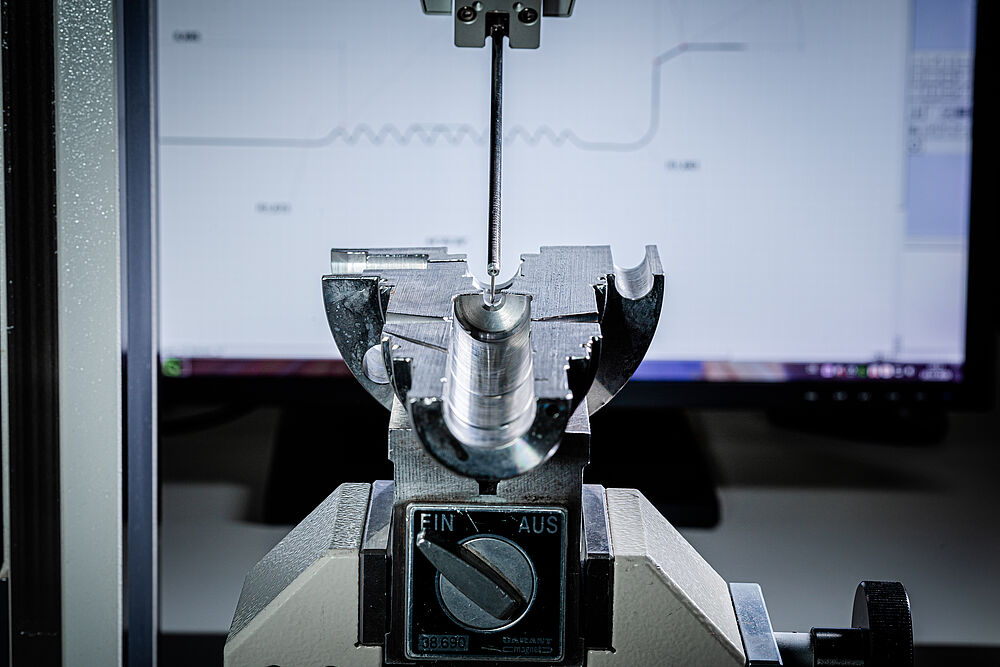

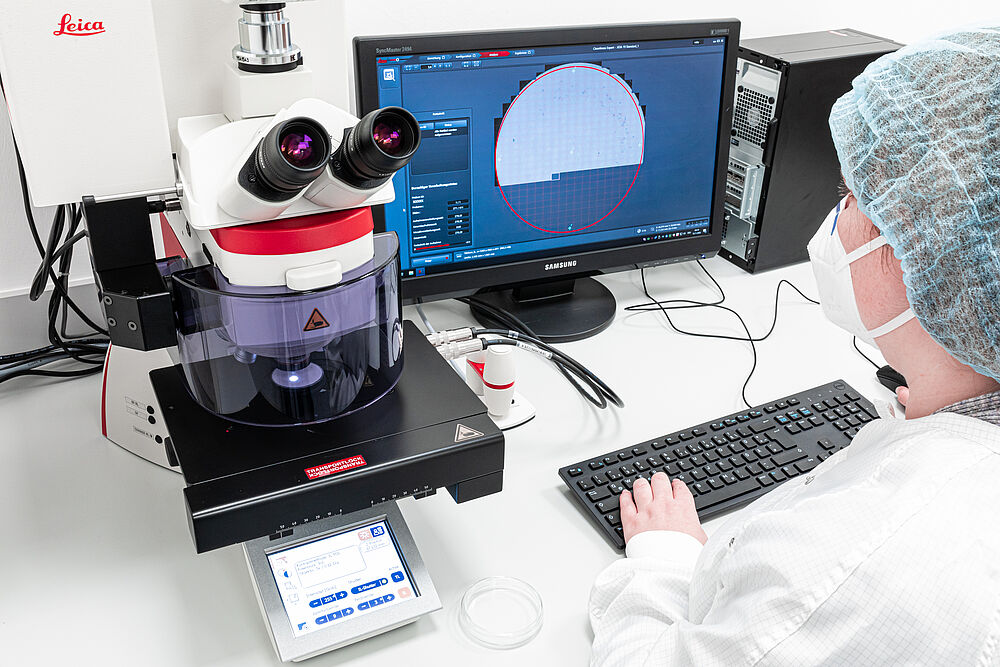

Equipped with tactile coordinate measuring machines, surface measuring devices and a large number of other measuring and testing equipment, Custom Machining is able to master almost all metrological challenges. Most of the processing machines are equipped with 3D measuring probes so that process reliability and accuracy in the manufacture of the components can be guaranteed at all times.

Custom Machining carries out process-accompanying measurements and product audits in order to carefully monitor the quality of the products and processes. The determined data are recorded with CAQ software.

Quality Assurance employees have the following qualifications and knowledge: Six Sigma, AUKOM, IATF16949, VDA6.3, GPS standards.