Hans Rosenberger senior

History

Milestones in the Company's History

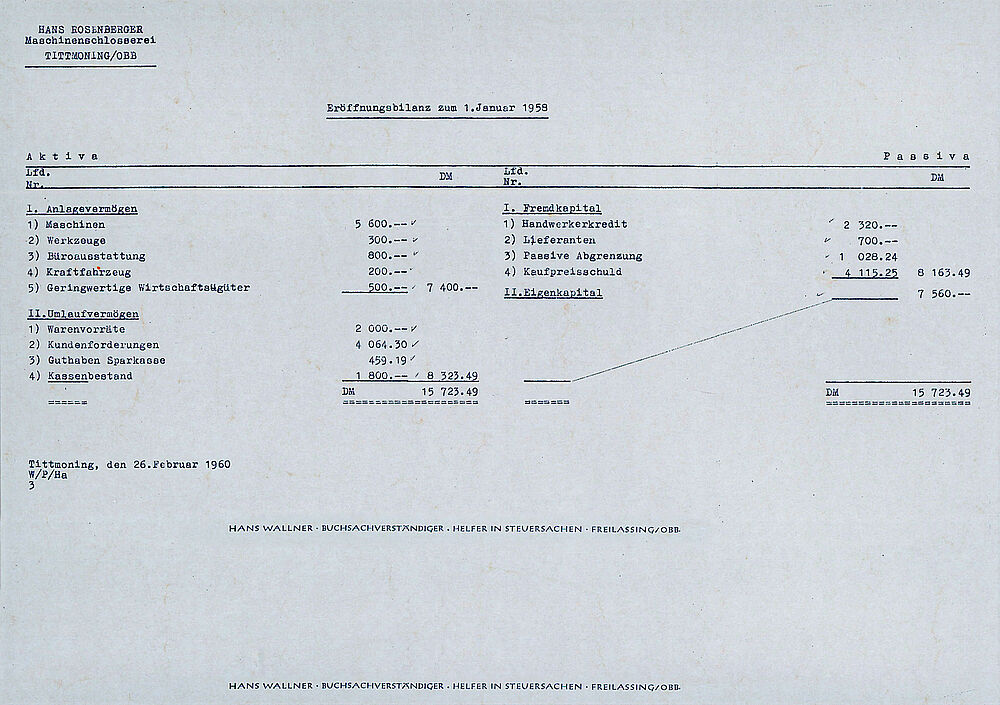

1958

After the death of his father-in-law, Hans Rosenberger senior takes over his locksmith's shop in Tittmoning, Upper Bavaria, and establishes his own company: Hans Rosenberger Maschinenbau. The business also offers contract manufacturing with the processing of raw metal parts for the commercial vehicle industry. This is the beginning of the now independent Custom Machining division of Rosenberger

1959

For the machining of larger cast parts Rosenberger makes its first significant investment - in a core lathe. MAN places an order to manufacture components for its booming truck production

1968

Rosenberger moves into today's company premises in neighboring Fridolfing. The main priority is to structure and organize the growing company

1973

In the mechanical engineering sector sales decline for the second year in a row. The connector business cushions the losses overall but the ongoing recession as a result of the oil crisis creates a difficult situation. The following year sales at Rosenberger‘s high-frequency technology division - active since 1967 – overtake the classic mechanical engineering division

1979

Over the next few years the Rosenberger site continuously modernizes. In order to meet market requirements the company expands its machine park to enable greater production capacities. The investments pay off and soon deliver record sales

1985

In mechanical engineering, orders are declining. In view of the high unit wages, many customers are investing in automatic machining centers to bring previously outsourced work back in-house. With numerically controlled machines Rosenberger remains technically up-to-date and competitive

1996

Although Custom Machining is being overshadowed by the enormous expansion of the connector business it is developing into a respected and efficient manufacturing partner for numerous customers - from various industries. With a spacious new building, Rosenberger creates the conditions for guaranteeing optimal production processes.

In the following years, investments are made in fully automatic machining centers while measuring devices are perfected - sales are increased

1998

At Custom Machining all signs point to expansion: Rosenberger builds a warehouse on the enlarged site and invests in high-speed precision machines to meet the requirements of new customers

2005

Having moved into new halls with its own driveway and parking lot in 2004, Custom Machining commissions three future-oriented machining centers for large precision parts. The increased in-house production capacities make purchases of individual metal parts largely unnecessary

2006

Rosenberger continued to invest in Custom Machining: four new machining centers are installed in anticipation of long-term orders from an important customer. An additional warehouse creates even more space and options for optimizing production processes

2007

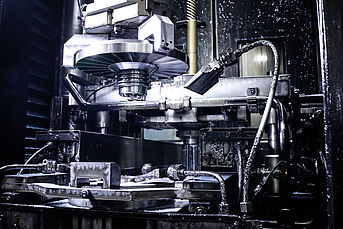

The first double-spindle turning-milling centers for the complete machining of complex components goes into operation

2009

Sales halved due to the financial crisis. However, through well-considered measures, the company survives the crisis without losses

2011

Further pioneering double-spindle turning-milling centers are designed and purchased as part of a cooperation project with a machine manufacturer. This enabled even more efficient complete machining of highly complex parts

2014

Custom Machining received its first order from the car industry for the production of gearboxes in automotive quantities.

The first robot cell with automatic loading and unloading, deburring, cleaning and camera-based position detection is installed

2015

An electronic shop floor management system is introduced for all production areas. Custom Machining revises and optimizes manufacturing processes according to LEAN methods

2018

5-axis milling is expanded by two systems and a restructured production area put in place in preparation for upcoming automation measures

2020

Six robot cells for the fully automated production of complex components go into operation

Today and the Future

Over the course of 60 years Custom Machining has developed into a high-tech system supplier setting new standards for technology, competence and customer satisfaction. Innovative, quality products will continue to be manufactured exclusively at Rosenberger's headquarters in Fridolfing, Bavaria: genuinely "Made in Germany".